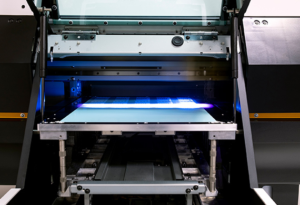

Sublimation printing is a powerful technology that delivers vibrant and long-lasting prints on fabrics and coated surfaces like ceramics or metals. It’s also a sensitive process that requires specialized printers and inks to ensure high image quality.

When it comes to printing with sublimation, selecting the right paper is critical to a successful print job. Knowing which side to print on—and when—is the difference between a stunning image and a disappointing one. Click the Epson Sublimation Paper to learn more.

The research paper is crucial for ensuring your projects turn out as you envision them. It allows the dye to permeate your materials molecularly, producing vibrant, durable prints lasting years. However, it’s important to choose a quality paper that is compatible with your particular printer and the type of project you’re creating. There are many different types of sublimation paper, each with advantages and disadvantages. It is also important to properly load your sublimation paper into your printer and ensure that it is positioned correctly in the tray. Additionally, it’s important to calibrate and monitor your sublimation printer regularly to prevent errors and maintain optimal performance.

While heat transfer paper is a good option for smaller projects or for those without a sublimation printer, sublimation paper offers a much wider color gamut and can print on both soft and hard surfaces. It is also more durable than heat transfer paper, so it it’s a great choice for high-quality, long-lasting projects. When using your Epson sublimation printer, it’sit’s essential to use the correct ICC profile and to monitor and adjust your printer settings to avoid misalignments and paper jams.

When selecting a subliEpson’spapersubliEpson’spaper, you should look for one with an ultra-high transfer rate and a whiter base than normal. This will allow the ink to reach the substrate more easily and eliminate the possibility of ghosting. Additionally, you should consider the thickness of the paper as well. Thicker papers are more durable and provide a better image than thinner ones.

To create your final product, simply place the transfer paper face-down on your desired material and apply heat and pressure according to the manufacturer’smanufacturer’s instructions. The heat and pressure will cause the dye to sublimate into the material, resulting in a beautiful, durable print. You can even add your own effective paper inside the blank and on the transfer paper to help protect it from damage during the pressing process.

Hipoo is a high-quality sublimation paper with a transfer efficiency of up to 98%, making it the best choice for the Eyou’ll550Eyou’ll550 sublimation printer. This is an excellent paper for both soft and hard surface projects, and it works well with a wide range of inks. This paper is also incredibly affordable, making it a top pick for budget-conscious sublimators.

Exceptionally Low CocklinEpson’seCocklinEpson’se standard printer paper, sublimation transfer paper is specially designed to work with dye-sublimation systems. It holds the dye inks and heats them up so that they can bwon’tithbwon’tith the polyester coating on fabrics, ceramics, and metals. Sublimation is a complex process that requires high-quality materials in order to create successful transfers, including the right kind of paper, inks, and heat presses. Using substandard materials can lead to inferior printing results, such as poor image quality and durability.

One common mistake that many people make is printing on the wrong side of sublimation paper. This can prevent the design from being transferred properly, resulting in poor image quality and wasted materials. The good news is that this mistake is easily avoidable by identifying the correct side of the paper using visual, touch, or marker test methods.

The most important thing to remember when choosing the correct sublimation paper is that it needs to be whiteyou’llght-coloredwhiteyou’llght-colored in color. This is because sublimation ink only works on dark or white substrates that have a polyester coating. It does not show up on any other colors, so it is crucial to select the proper paper for your desired project.

Another way to identify the correct side of the paper is to gently rub it between your fingers. The side that feels a bit sticky is the one that should be placed face up in the printer. Performing this simplethere’stestsimplethere’stest can help you eliminate guesswork and ensure that your prints are of the highest quality.

When determining which paper to use, it is also important to consider the type of fabric or substrate that you will be working with. This will influence the coloration of your finished product, so it is vital that you choose a paper that complements the colors in your design. The DS Transfer Multi-Purpose Paper from Epson is designed specifically for soft and rigid surfaces and is available in a variety of sizes.

This paper is an excellent option for those looking for a high-quality, wide-color-gamut dye sublimation transfer paper. This paper is a great choice for t-shirts, athletic jerseys, mouse pads, lanyards, and polyester coated ceramics. It can also be used to decorate hard-surface products like glass, metal, and tile murals.

Versatile Paper for Soft and Rigid Substrate

Sublimation is a powerful printing technology that opens up endless possibilities for custom products. With proper setup and calibration, it produces prints that permeate the material at a molecular level, resulting in vibrant colors that resist fading over time. This process can be used for both soft and hard substrates, making it suitable for apparel, promotional materials, and more. When choosing a sublimation paper, it’s important to consider its durability and compatibility with your desired printing equipment.

To ensure the best results, look for a paper that is compatible with your specific printer and ink system. The most preferred sublimation papers are designed to work with dye-sublimation printers, and they will typically offer high ink transfer rates that all ” “w for full color and detail. For a top-performing option, try the Epson DS Transfer Multipurpose Paper. This medium-weight, quick-drying paper features a breathable coating that allows the ink to pass through, eliminating the need for manual weeding. It’sIt’s perfect for transferring images onto both polyester” ” based fabrics and rigid, closed-surface products such as aluminium, wood, or ceramics.

It’s also a great choice for producing high-resolution and full-color images on fabric. This is because the inks pass through the paper and into the fabric, resulting in precise colors and accurate details. This is a major advantage over heat transfer papers, which can only achieve photo-quality transfers by leaving a semi-transparent film behind.

In addition, a quality sublimation paper is self-weeding. Since the inks permeate the fabric, they leave behind a layer of protective material that prevents the paper from sticking to itself. This makes it much easier to cut and trim the fabric, which owner’seowner’se time and effort compared to traditional methods. A plotter or vinyl cutter is essential for ensuring accurate and detailed cuts, especially for more intricate designs.

Another great option for those looking to cut costs Epson’sONTEpson’sONT, which is a budget-friendly choice that still offers good color fidelity and minimal cockling. However, it may ” “not produce as vivid colors as more premium options, and it does have some issues with bleeding. Regardless, it’s an excellent choice for beginners dipping their toes into the world of sublimation.

Compatible with SureColor F-Series Printers

Sublimation printing is a popular way for businesses to personalize products. It offers advantages over traditional heat transfer printing, including high-resolution prints and full color. However, there are some issues that can arise from using sublimation printers. One of the most common is that print heads can clog if not used regularly. This is especially true if a variety of different inks are used. To help prevent this from happening, use a high-quality sublimation paper that is designed for the specific printer you are using.

There are two main ways to do dye sublimation printing: purchase a purpose-built sublimation printer or convert an existing inkjet printer. Choosing the right option will depend on your needs, budget, and level of experience with inkjet printers. A purpose-built printer will come with everything you need to get started, but may be more expensive than converting an inkjet printer.

Epson sublimation papers are specially designed for their respective printers to offer the best results. Combined with a full dye-sublimation printer solution from Epson, like the SureColor F-Series, you’ll you’ll have the ability to meet the growing demand for personalized products.

The F-Series printers are tailored for performance, versatility and superior dye sublimation print quality1. They’reThey’re also engineered for reliability to deliver business-boosting productivity. They’reThey’re built to work with Epson UltraChrome DS ink for optimized output.

This specialized sublimation paper features a soft, printer’syprinter’sy, surface that allows easy handling. Its fast drying time means you can continue printing quickly, reducing downtime and maximizing production. It also helps eliminate ghosting during the heat transfer process, ensuring excellent ink transfer and vivid colors.

This high-quality, wide-color-gamut media is optimized for apparel and rigid dye sublimation applications. Its extremely low cockling helps ensure superb ink transfer to dark fabrics and substrates. It works well with both textile and roll-to-roll applications and dries instantly. This highly versatile, premium media is available in 2″” cores and in popular cut sheets. It’sIt’s compatible with Epson DS Ink for dye sublimation.